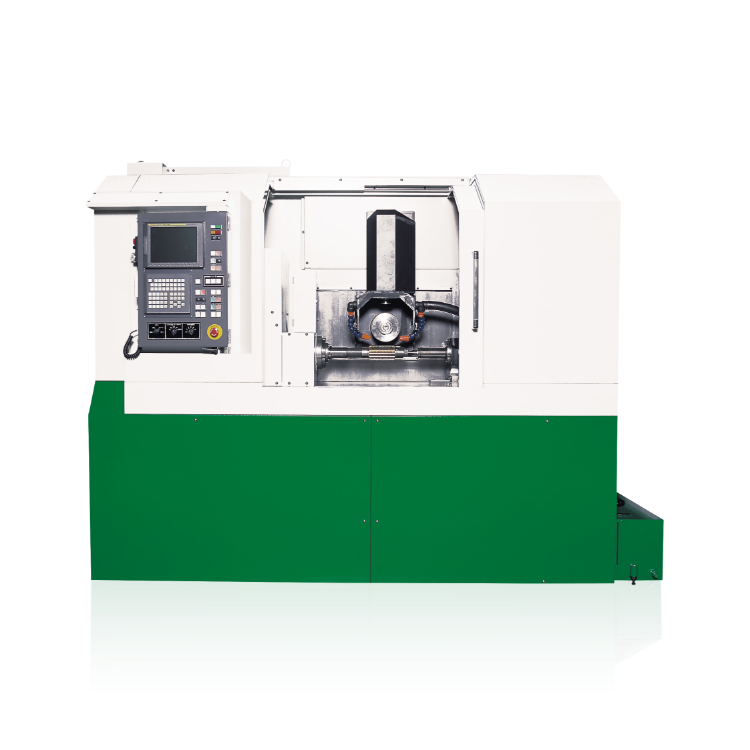

6 Axis-CNC Hobbing Machine

KN152

Ideally suited for Hobbing Long Shaft Parts

A Complete Dry Cut Hobbing Machine

(Wet Cut Hobbing Machine or Wet/Dry Cut Hobbing Machine is optionally available.)

- Max. Workpiece Diameter

- 150 mm

- Max. Module

- 4

Feature

For details, click on the Icon.

-

Vertical

Hob Machine -

Hand

Scraped

Guideways -

Zero

Backlash

Table -

Auto-mation

-

In Machine Chamfering Unit

-

Hard Hobbing

-

Program

Typical Parts Hobbed

・ Long Shaft Gear

・ Automotive Transmission Gear

・ Geared Motor

・ Compact Reduction Gear

・ Motorcycle Gear

・ Agricultural Machine Gear

Precision Hobbing of Long Shaft Parts

Perfect for hobbing long shaft parts or, shafts with multiple splines/gears. The KN151 has 400 mm of Z axis (axial) stroke, longest for this size of hobbing machine in the industry, and 645 mm of distance from table top to tailstock center.Also, Hard Hobbing, (finish hobbing process for hardened gears) produces a highly accurate tooth form, an overall increase in gear quality, at a low cost when compared to the grinding process it can replace.

Integrated Column and Tailstock Column - Allows for excellent Thermal Stability and Accessibility!

The integrated column and tailstock column increases the thermal stability and minimizes the O.B.D. (size) variation from a cold start due to thermal deformation allowing for superb machining accuracies.

Additionally, the tooling area is wide open, making the operator’s accessibility to the hob cutter and jig fixture quite convenient. A part transfer unit such as auto part loader can easily be installed in this area while still allowing a compact machine foot print.

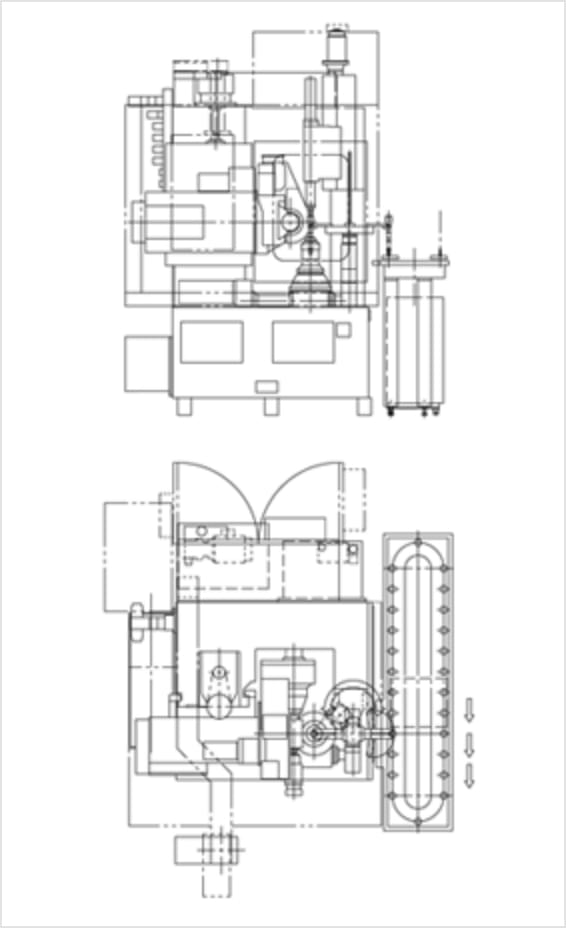

Smooth Chip Removal

The KN152 was specifically developed as a complete dry cut hobber. The machine has increased slanted sections around the bed and column, and the hob saddle is protected by exit chute covers with few horizontal sections allowing rapid chip removal from the cutting tool area. Also, the new “Hanging” Style auto loader aids in an efficient and smooth chip removal.

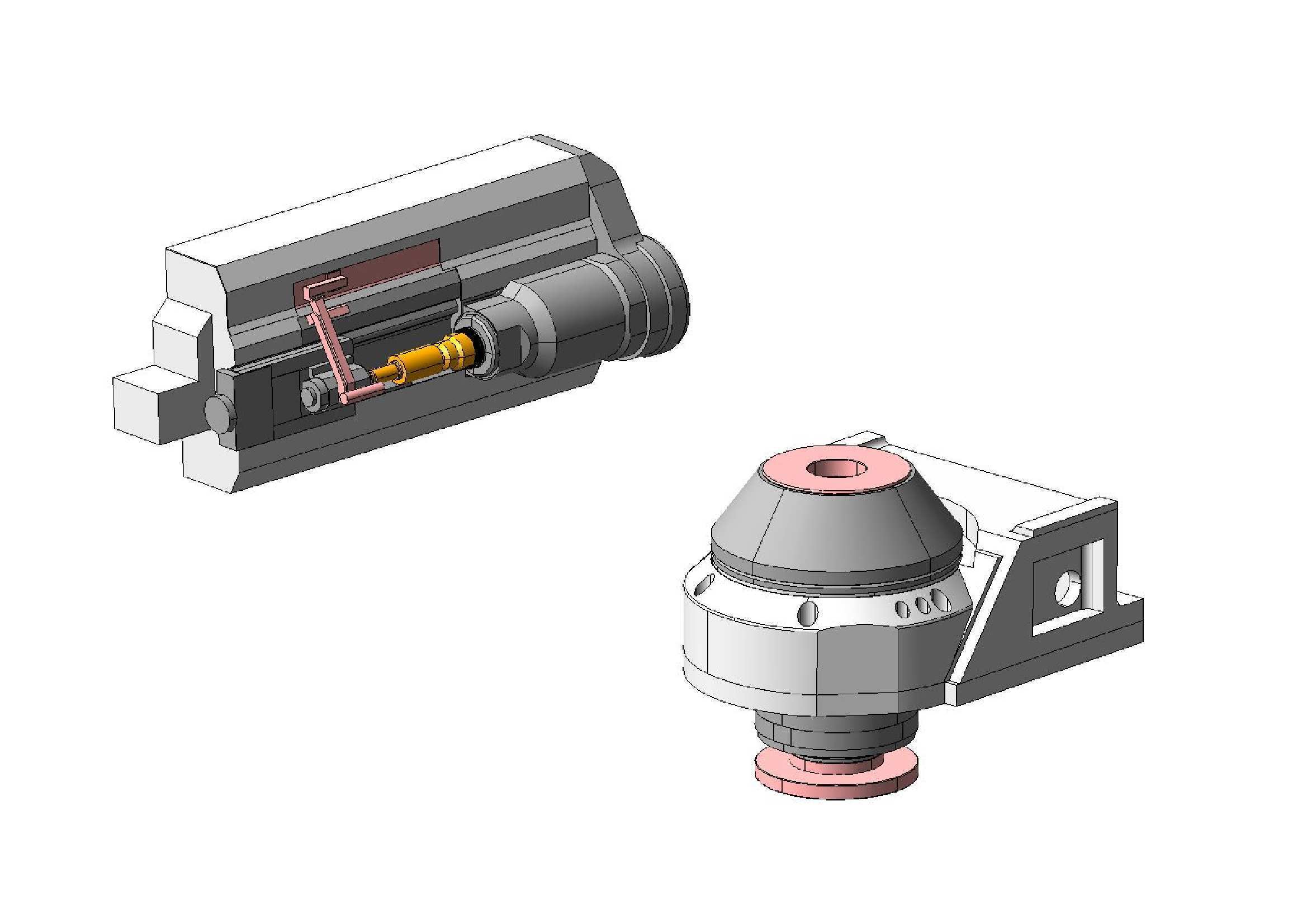

An Innovative Hob Head and Work Table Design specifically for Highly Accurate Finish Hobbing (Special Option)

A new highly accurate hob head utilizing a built-in spindle motor and/or a highly accurate work table design with a built-in servo motor is optionally available for extremely accurate and high speed hobbing of small module gears. The high speed direct drive motor system of the hob head and work table delivers highly accurate finish hobbing equivalent to gear grinding or hard hobbing.

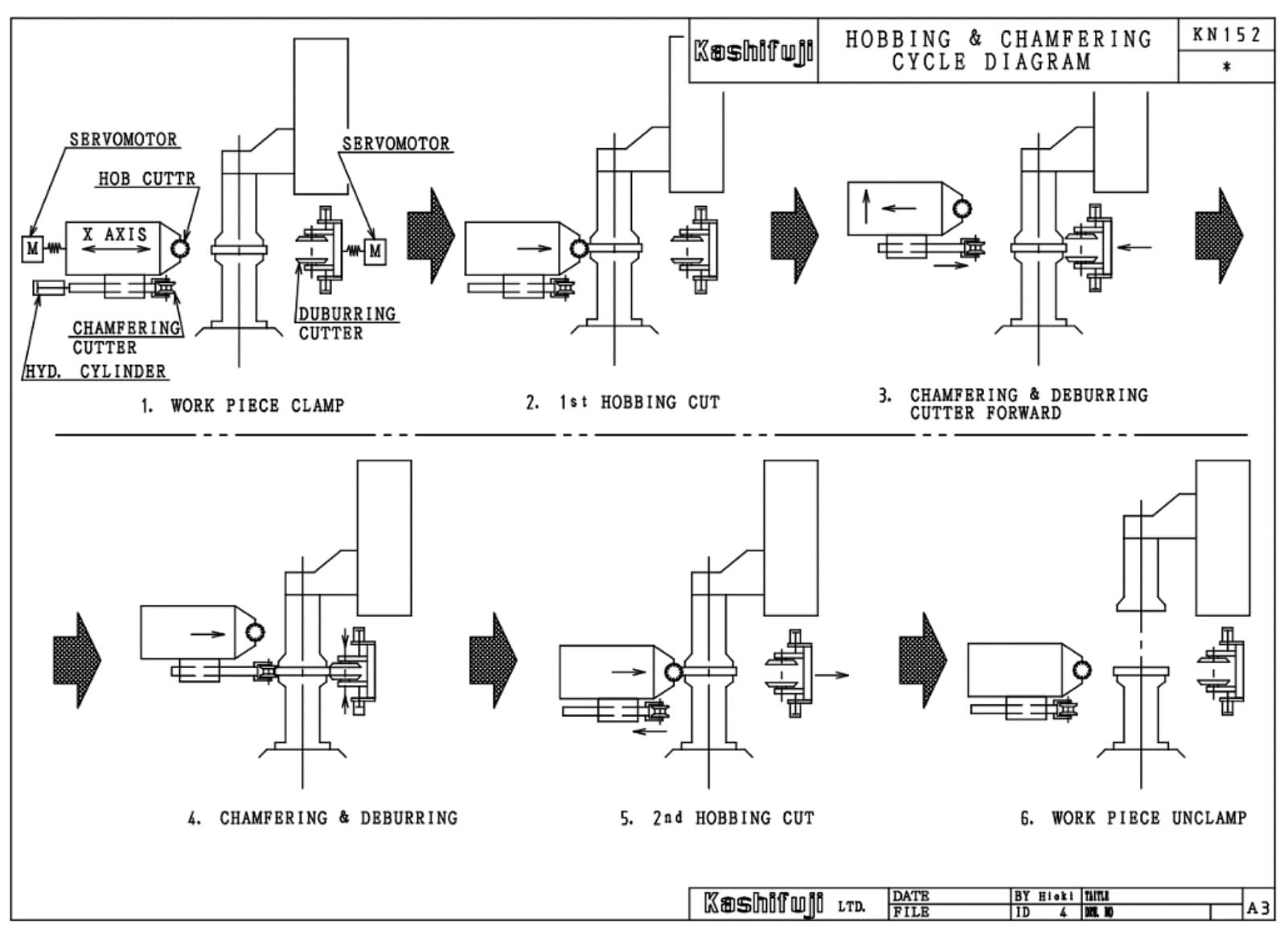

Rotary Chamfering Device(Special Option)

Chamfering and deburring can be handled in the tooling area of the KN152, after the completion of the hobbing cycle by using the Rotary Chamfering Device. Additionally, secondary burrs generated during the deburring phase, can be removed by rehobbing. “Hardened” secondary burrs remaining on tooth flanks which can remain after heat treat, can damage the grinding wheel used in finishing processes such as gear grinding and/or honing. Elimination of secondary burrs increases grinding wheel life. The production line length can be reduced due to the combined operations of hobbing, chamfering and deburring. The KN152’s Rotary Chamfering Device can also accommodate Shaft Gears.

Specifications

-

Specs

- Max. Workpiece Diameter

-

150 mm

- Max. Module

-

4

- Max. Axial Feed Travel

-

400mm

- Max. Hob Head Swivel

-

±45°

- Max. Hob Size: Diameter x Length

-

130×180mm

- Max. Hob Shift Travel

-

150mm

- Max. RPM of Hob Spindle

-

150~1,500rpm

- Max. RPM of Work Table

-

150rpm

- Weight

-

9,000kg

- Floor Space: Length x Width x Height

-

1,815 × 2,475 × 2,750 mm

Product Catalog

You can download the PDF data of product catalogs by adding the desired catalog to the list and filling out the form at each download link.

-

KN152

downloadIf you want to view other catalogs or download multiple catalogs, visit the

catalog download page.

Inquiries about This Product

We are dedicated to a fast response to your request, and will make every attempt to respond in a timely manner. Requests received on Holidays or Weekends will be handled on the next business day in most cases.

-

Contact by E-mail

You can e-mail us through the forms below.

Contact FormSSL-EnabledAll your personal information entered into the forms is safely protected using a secure VeriSign SSL encryption session.

-

Contact by Phone

Head Quarters Overseas Sales Dept.+81-75-661-5271

Hours : Monday ~ Friday, 8:00 a.m. ~ 16:30 p.m. (Japan)

(Except for New Year’s, National, Summer and other Company Holidays) -

Contact by FAX

Head Quarters Overseas Sales Dept.+81-75-661-5270

Please use the FAX sheet below.

Product and Other Inquiries Request for Quotation for Spare Parts or an Order for Spare Parts

Vertical Hob Machine

Changing Fixtures, Hob Cutters or Workpieces (manual loading) is far simpler and faster than in a horizontal hobber as compared to a vertical hobber. As the workpiece /fixture are positioned vertically, they are very easy to exchange and accurately mount. The Hob Head of a vertical hobber allows great accessibility to the work table/tooling area and peripheral equipment (auto loader, transfer unit etc.) can be added without reducing operability!

Hand Scraped Guideways

Kashifuji hand scrapes the guideways on all its hobbing machines to create a platform that dampens and absorbs the intermittent cutting forces that are inherent to hobbing process. This feature allows many years of use while still maintaining superb hobbing accuracies.

Generally, machining has limited achievable accuracies due to friction created distortions and/or internal stress relief produced during the machining process. Variations of temperature and humidity during the machine process can also reduce accuracy. Kashifuji utilizes a hand scraped surface finish to assure highly accurate guideways that are not possible by any machining/grinding process.

Hand Scraping is a finish processing method that makes the guideways extremely accurate with an ideal flatness and straightness by manually removing metal in extremely small amount (1~3 micro meters) by the use of a hand tool called a "Scraper". This hand tool has a carbide tipped single edge blade with a blunt angle. This tool is used to relieve the surface tension (create numerous, evenly distributed small, shallow dips or reliefs) in the guideway surfaces. Scraping produces a very flat surface, and the "shallow divots" retain oil which creates smooth sliding surfaces while reducing wear.

Hand scraping is a labor intensive process. The guideway surfaces are painted with a “dye” then rubbed with a reference straight edge, the dye collects on the highspots. The highspots are then removed by “hand scrapping”. This process (applying dye, rubbing & scrapping) is continually repeated until approximately 30% of the guideway surface is “relieved” producing ~70% bearing surface. This process produces an extreme flatness.

Hand scraping is referred to as a "Master's Skill". Kashifuji's skilled craftsmen are able to make accurate micro-meter scraping marks compensating for variations caused by material or temperatures changes. The "scraping pattern" produced, is often referred to as an "art form", and is unique to each craftsman. It takes many years of tedious, difficult work to acquire the experience & skill to become an accomplished Kashifuji "Scraper".

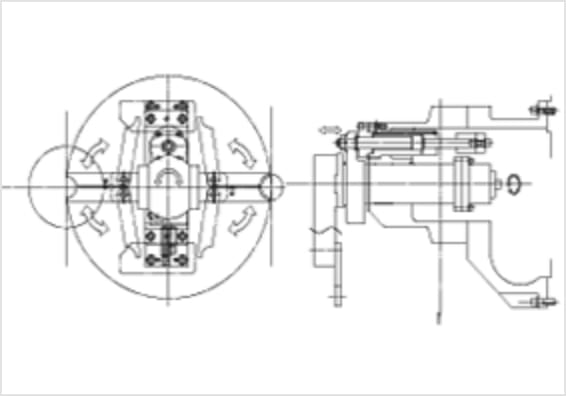

Zero Backlash Table(Work Table Backlash Eliminator)

Kashiufji designed and developed a hydraulically controlled split worm Work Table Backlash Eliminator.

This device creates a Zero Backlash condition for the work table under all cutting conditions.

The backlash eliminator suppresses work table vibrations assuring smooth and highly accurate work table rotation. The rotational accuracy of the work table will not degrade with use, as the device is self-adjusting (maintenance-free).

The backlash eliminator allows consistency in hobbing accuracies especially when hobbing large pitch gears, hobbing with a carbide skiving hob cutter and opposite hand hobbing (lead angle of a hob cutter is opposite of the helix angle of the part).

Automation

Numerous styles and types of auto loaders, conveyors or part stockers are available for automatic part transfer. All loader design are labor saving and increase efficiency.

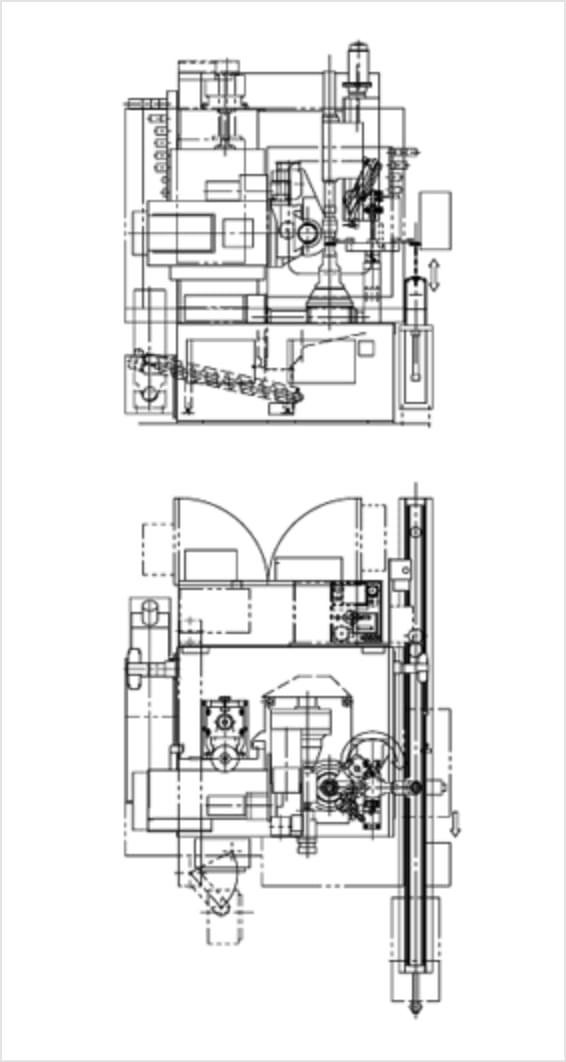

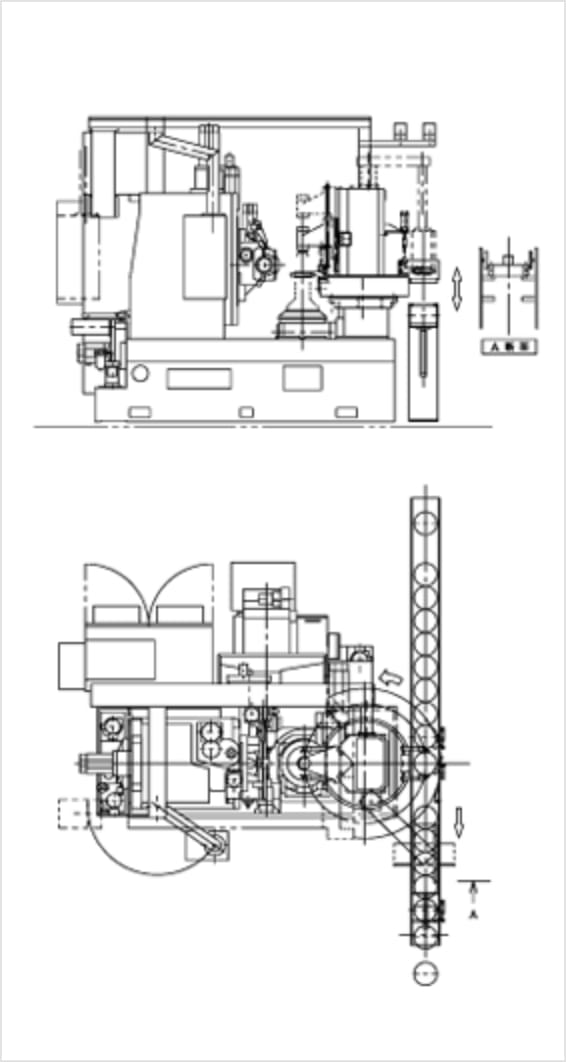

Basic 2-Arm Auto Loader(KN80, KN152)

Basic Ring Loader

(KE201/251、KA220/400)

Transfer Example for Flat Gears

Transfer Example for Flat Gears

Transfer Example for Shaft Gears

Transfer Example for Shaft Gears

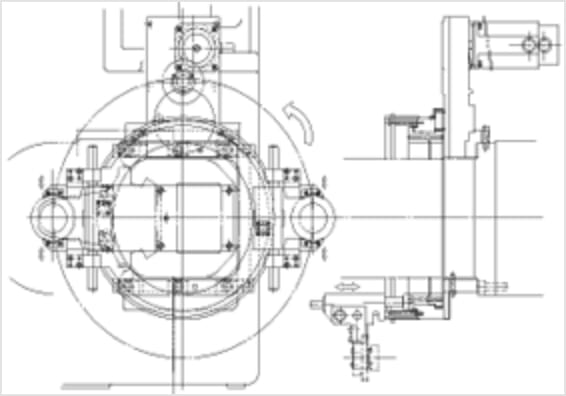

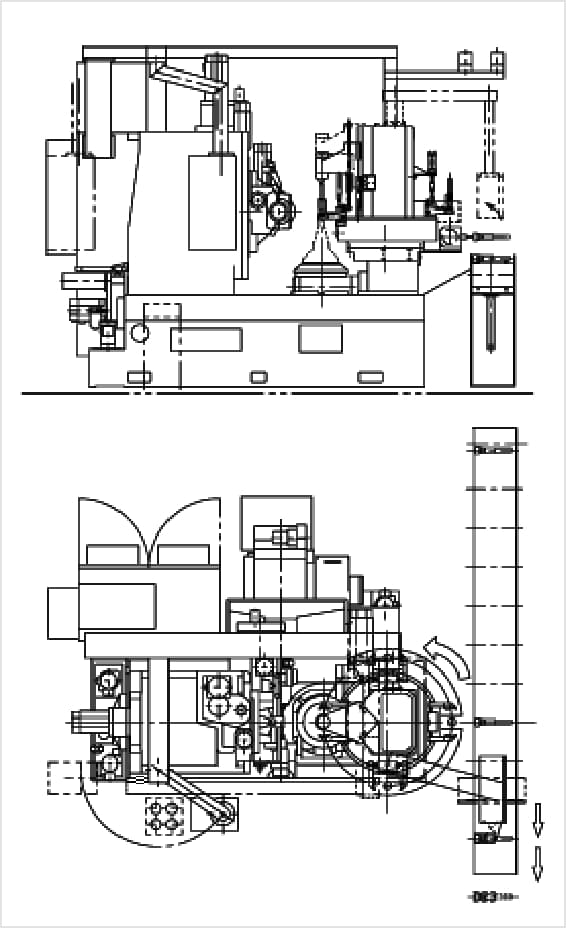

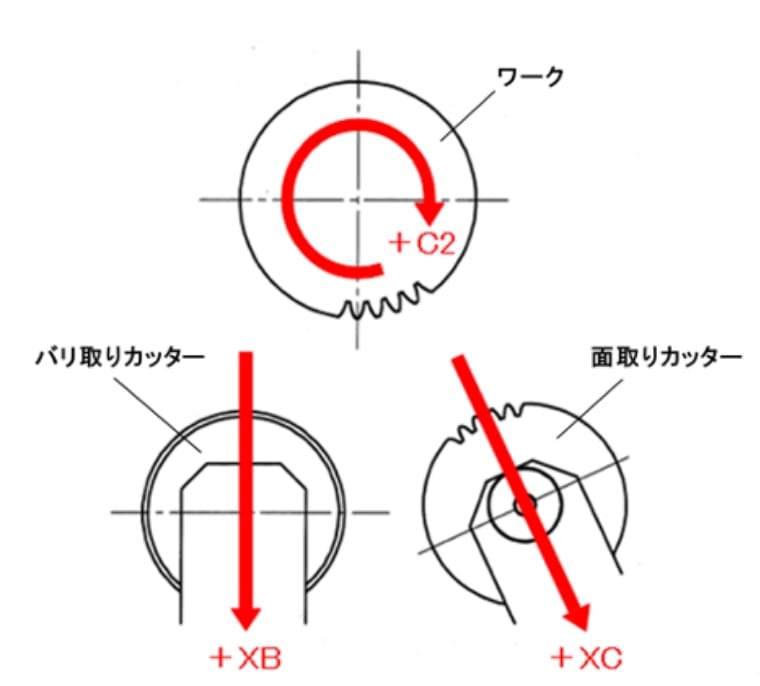

In-machine chamfering unit (optional specifications)

<Stock removal process using a chamfering cutter>

The use of an auto part loader device enables chamfering and deburring during the hobbing process. By effectively using the open space of the machine and by making the chamfering tool axis and the deburring tool axis independent, it is easy to change / adjust the tooling from the machine front operation side. In addition, the combination of hobbing, chamfering and deburring reduces the line length and cycle time.

By installing a chamfering device underneath the hob head, it is possible to chamfer the part in the tooling area after hobbing and deburr the part in the open space. Additionally, the secondary burrs caused by deburring can be removed by re-hobbing. The removal of secondary burrs prevents the tooth flanks from getting damaged due to the hardened secondary burrs in the finishing processes such as gear grinding or honing, contributing to improved tool life. The combination of hobbing, chamfering and deburring reduces the line length. Also, it is possible to process a shaft gear.

<Milling Method by tracing using a carbide rotarty end mill>

The use of an auto part loader device enables chamfering during the hobbing process. Using the machine open space effectively, the rotating carbide end mills lightly touch the rotating part allowing chamfering for both top and bottom ends of the part. Chamfering is possible using the same rotarty end mill even if the part type is chgangred.

Hard Hobbing

Hard Hobbing is a finish hobbing process for hardened gears.

There are two kinds of Hard Hobbing processes that use carbide hobs. One is "Finish Hobbing" in which hardened gears are "finished" after the initial tooth cutting. The other is "Hardened Solid Gear Hobbing" where hardened solid gear blanks are finished hobbed.

Kashifuji has developed an Auto Part Orientation Device utilizing a special non-contact sensor that quickly and accurately orientates gear teeth to the hob tool.

Finish Hobbing

Hardened Solid Gear Hobbing

Auto Part Orientation Device

Programming

Programs are created by only inputting part gear data, hob data and cutting conditions. After the completion of the programs, hobbing will be automatically performed by selecting the part number.

Optional crowning, relieving and/or taper hobbing cycles are easily performed. Simple and easy-to-operate hobbing programs are available for a wide variety of production situations, from mass production to special prototype hobbing.